7 Reasons Builders Trust Marine Lumber for Longevity

Durability and resilience are two of the most critical factors builders consider when selecting materials for coastal, outdoor, or high-moisture construction projects. Marine lumber—engineered to resist water damage, decay, and warping—stands out as a superior choice for long-term performance. Whether used in docks, decks, or boat structures, this material offers the reliability professionals need to build with confidence. For contractors and homeowners alike, choosing high-quality marine lumber ensures every project is built to last and withstand the harshest environmental conditions.

1. Exceptional Moisture Resistance

Marine lumber is specifically designed to endure constant or intermittent exposure to water without losing its structural integrity. It is treated with waterproof adhesives that prevent delamination, even in saltwater environments. This resistance makes it ideal for use in docks, marinas, and waterfront construction. Builders trust marine lumber because it retains its shape and strength where traditional wood would swell, crack, or rot. Consistent moisture protection means fewer repairs and replacements over time.

Marine lumber’s durability also extends to its resistance against temperature fluctuations and UV exposure—two common culprits of material fatigue in outdoor construction. Traditional wood can expand and contract with changing weather, leading to warping or surface cracking over time. Marine-grade lumber, however, is engineered to maintain stability even under intense heat or freezing temperatures. This consistent performance ensures structures like boat decks and docks remain safe, stable, and visually appealing season after season.

In addition, marine lumber’s superior sealing and bonding properties make it an excellent foundation for protective coatings or stains. These finishes adhere more effectively to its smooth, uniform surface, enhancing its natural resistance to water penetration and environmental wear. Builders often choose to pair marine lumber with specialized sealants for added longevity, ensuring the material performs optimally in both freshwater and saltwater conditions. This layered protection makes marine lumber one of the most dependable and versatile materials for coastal and outdoor construction.

2. Superior Structural Strength

Unlike standard plywood or untreated wood, marine lumber features multiple cross-laminated layers bonded under high pressure, enhancing both stability and load-bearing capacity. This construction minimizes the risk of splitting and ensures even weight distribution. Builders rely on this durability for projects that demand high performance under stress, such as pier foundations and load-bearing decks. The added density not only improves structural integrity but also ensures reliable long-term performance in both wet and dry environments.

The dense composition of marine lumber also helps it resist impact and surface abrasion—qualities that are especially important for high-traffic or heavy-use applications. Whether used in commercial docks, seawalls, or waterfront walkways, this toughness allows it to endure daily wear without compromising strength or appearance. Builders appreciate that marine lumber maintains its dimensional accuracy, reducing maintenance demands while ensuring continued safety and stability for years to come.

Additionally, the precision engineering behind marine lumber ensures that each panel or board meets strict quality standards. Unlike ordinary wood, which can vary in grain and strength, marine lumber is manufactured for uniformity. This consistency simplifies installation and reduces waste, as every piece performs predictably under pressure. The result is a reliable, high-performance material that gives builders confidence in long-term project outcomes—particularly in environments where reliability and resilience are nonnegotiable.

3. Resistance to Rot and Fungal Decay

Marine lumber undergoes specialized treatment processes that protect it from biological threats like mold, fungi, and wood-boring organisms. In humid or coastal regions, this resistance is a major advantage. Regular wood, when exposed to damp conditions, often deteriorates rapidly—compromising both appearance and safety. With marine lumber, builders can count on materials that maintain their quality even after years of exposure to the elements, making it a sustainable and cost-effective choice for long-term projects.

This biological resistance also reduces the need for harsh chemical preservatives or frequent retreatment, aligning marine lumber with environmentally responsible construction practices. Builders working on eco-sensitive waterfront projects often prefer it because it minimizes contamination risks to surrounding ecosystems. By resisting decay naturally, marine lumber extends the life of marine structures while lowering maintenance frequency and environmental impact—two priorities in sustainable design and coastal development.

In addition, marine lumber’s resistance to biological deterioration enhances its visual appeal over time. Unlike untreated wood that darkens, cracks, or grows mildew, marine lumber retains its clean, professional appearance even in demanding climates. This long-lasting aesthetic quality makes it ideal not only for functional installations like docks and seawalls but also for decorative outdoor applications such as pergolas, railings, and waterfront patios. Builders gain both durability and design consistency, making marine lumber a preferred material for projects that must perform beautifully under pressure.

4. Proven Longevity in Harsh Environments

Marine-grade materials are engineered for endurance. According to The Spruce, properly maintained marine-grade plywood can last up to 20 years or more, even in wet conditions. This remarkable longevity is a key reason builders trust marine lumber for critical outdoor applications. Its durability reduces the need for frequent maintenance, saving both time and money. Whether constructing coastal boardwalks or boat components, this long service life ensures reliable performance for decades.

This extended lifespan also provides measurable long-term value for builders and property owners alike. Fewer replacements mean reduced material waste, lower labor costs, and greater overall project efficiency. Marine lumber’s endurance helps stabilize budgets across the lifetime of a structure, making it an investment that continues to pay dividends years after installation. Builders appreciate this financial predictability, especially in projects exposed to harsh elements where other materials would degrade much faster.

Furthermore, the reliability of marine lumber enhances safety and peace of mind. Structures built with it are less likely to suffer from hidden decay or sudden failures caused by moisture infiltration. This level of dependability is critical in marine and outdoor environments where performance cannot be compromised. For builders and developers, choosing marine lumber ensures that every component—from substructure to surface—maintains its integrity and strength under continuous exposure, reinforcing its reputation as one of the most trusted materials for longevity.

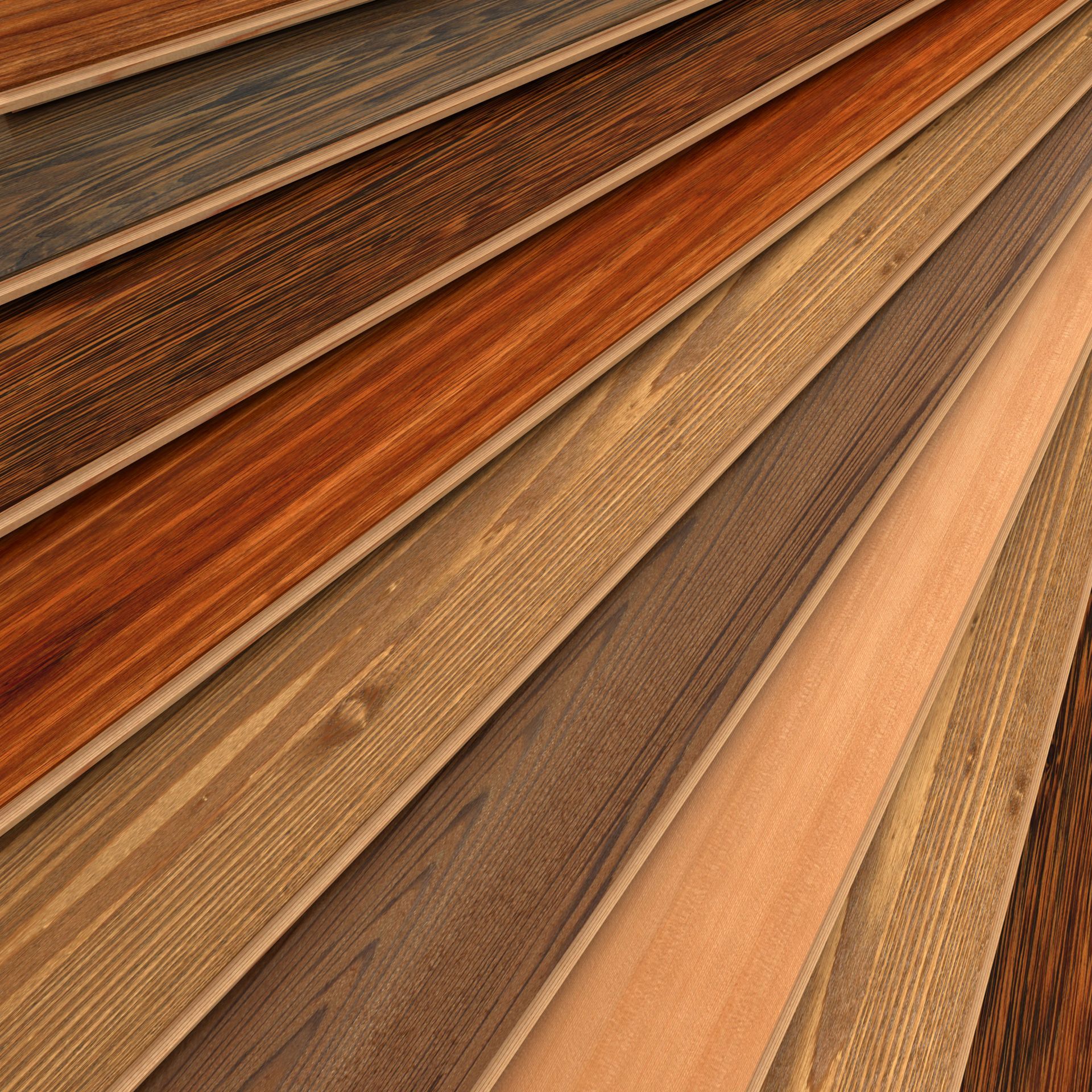

5. Versatile Applications and Aesthetic Appeal

Beyond its technical strengths, marine lumber offers visual appeal that complements its durability. Its fine grain and smooth finish make it suitable for both structural and decorative uses. Builders often use it for outdoor furniture, cabinetry, and custom millwork, where appearance matters just as much as resilience. Its adaptability across residential, commercial, and marine projects demonstrates why marine lumber remains a preferred choice among architects and contractors seeking both beauty and function.

6. Eco-Friendly and Sustainable Options

Modern manufacturing techniques for marine lumber emphasize sustainability without compromising quality. Many suppliers now source wood from responsibly managed forests and use low-emission adhesives to minimize environmental impact. Builders who prioritize eco-conscious design appreciate these options, as they combine performance with environmental responsibility. Choosing marine lumber helps reduce waste over time because its extended lifespan limits the frequency of replacements, contributing to greener and more sustainable construction practices.

7. Low Maintenance and Long-Term Savings

While marine lumber may have a higher initial cost compared to standard wood, its low maintenance requirements make it a smarter investment in the long run. The material naturally resists warping, cracking, and delamination, reducing the need for constant upkeep or costly repairs. Builders and property owners benefit from predictable performance and fewer disruptions due to material failures. Over time, marine lumber’s longevity and durability deliver significant savings while maintaining the structural and visual integrity of every project.

For professionals seeking durability, reliability, and long-term value, marine lumber remains unmatched. Its exceptional resistance to moisture, decay, and environmental wear makes it the go-to material for both structural and aesthetic applications. Builders trust it for everything from waterfront decks to boat components because it stands the test of time. Partnering with experts like Lumber Specialties Inc ensures you receive high-quality marine lumber tailored to your project’s needs. Contact Lumber Specialties Inc today to learn how their premium marine lumber can enhance the strength, beauty, and longevity of your next build.

Share On: